PreRamble

Kinematics discussion starts here below | GitHub repo for this build

All I wanted to do was tweak my Ender 3 V2 to to print a cover for transporting my Starlink Rectangle Dishy a little more securely. I also need to print a modification for the trunk/battery cover on my Ski-Doo Skandic SWT. To accomplish those tasks, I need a build plate slightly smaller than 400mm x 600mm. So 400 x 600 it is. I also wondered if I could leave the cover on the dish at times, and still have it work. To accomplish that, transitioning from a material like polycarbonate (PC) on the “radome” to something like ASA on the sides of the cover made multi material printing make some sense. Dual extruders are a good idea for printing different materials, and independent dual extruders (IDEX) further increases potential. But those questions are for another day.

Then the temperature at the cabin dropped to -40°F/C, then -47°F, then -55°F for a few days. Since my snowmachine doesn’t like to start below about -40°, I put a weather hold on other projects, and spent a hundred or two hours down the rabbit hole of 3D printers. Who knew I would have to pass through the realm of the Enraged Carrot Rabbit Feeder (ERCF MMU) to arrive in the here and now.

Along the way I passed through the forest of Sen 3D’s Ender IDEX mod. I waded through the river of kevinkakasam’s Belt Driven Ender Y-axis upgrade. I also got some great input from Mark at Ender Extender. Even though I already had the extrusions for my build, he graciously volunteered more expert information than I could have expected. So if upgrading your build volume is your main concern, check out the Ender Extender kits and parts. Pros and cons abound. Tangents, landmines, pitfalls and TeachingTech videos appeared with every YouTube search.

Let’s get one more question out of the way. Why not full coreXY? I dunno. Cost? I have a bias toward making the most out of what I have, and I have an Ender 3 V2. Another thing is that I couldn’t find much discussion of coreXY in a rectangle. It’s probably possible, but I don’t want to be a pioneer. 400 x 600 is already too big for most prints, and if my math is correct, 600 x 600 is bigger. Bigger means a lot of watts to heat the bed that’s wasted. Bigger means less space to work on other things in the lab.

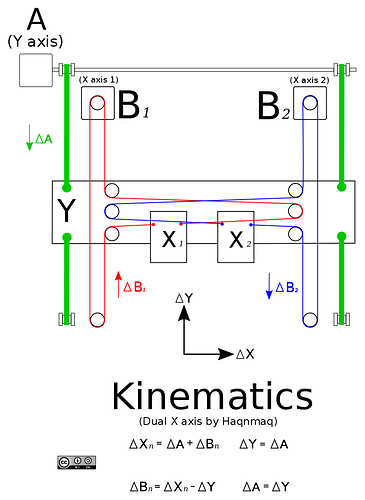

The belt routing that will be followed is the dual markforged kinematics. I will get a video or diagram up shortly explaining this.

The last update was 5 months ago, so off to the googles, which lead to this:

That doesn’t look exactly like Ankurv’s YouTube Short, but it looks 95% of the way there:

So that’s where we’re starting from, more research to follow. You’re welcome to join.